Cutting-Edge Rigid-Flex PCB Manufacturer Solutions

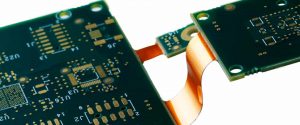

Rigid-flex circuit boards combine rigid and flexible PCB materials into a single unit, creating a durable and versatile platform for electronic devices. They provide stability for components while allowing the flexible sections to bend and fold, making them an ideal choice for devices that need to withstand extreme temperatures and vibrations. The best way to maximize the reliability of your rigid-flex board is to work with an experienced and capable manufacturer.

In the rigid flex pcb manufacturer industry, one size definitely does not fit all, and choosing the right rigid-flex contract manufacturer for your project is a critical decision. There are many factors to consider, including their quality, manufacturing capabilities, customer service, and pricing. Read on to discover how to select a partner who is the best match for your needs.

Unlike standard PCBs, which are typically fabricated from FR4 glass fiber epoxy resin, rigid-flex circuit boards are built from a stack-up of flex and rigid copper clad laminates. The rigid and flex layers are laminated together using heat, pressure, and adhesives to form a robust and reliable structure for your device. Rigid-flex circuits are a great option for complex designs because they can accommodate more components than traditional rigid PCBs and feature integrated connectors that simplify assembly.

Elevate Your Designs With Cutting-Edge Rigid-Flex PCB Manufacturer Solutions

A rigid-flex circuit’s ability to withstand environmental challenges is another key factor that contributes to its reliability. Designing for environmental resilience in rigid-flex circuit boards involves thoughtfully accounting for environmental conditions, such as temperature variations, humidity levels, and mechanical stress. By doing so, you can ensure your device’s long-term reliability.

The manufacturing process of a rigid-flex circuit board is highly sophisticated, and the equipment required to create it can be expensive. This can influence the overall quick turn rigid-flex circuit board cost. However, it is important to note that the price of your rigid-flex PCB can be greatly reduced by partnering with a company that offers flexible production schedules and volume discounts.

A cutting-edge RFPCB contract manufacturer can offer a variety of manufacturing services for your project, from prototyping to mass production. They will use the latest technology and high-quality materials to meet your needs. They will also be able to accommodate your project’s unique requirements. They can help you develop a custom manufacturing solution that is cost-effective and meets your exact specifications.

When selecting a rigid-flex contract manufacturer, ask for references from existing customers. Talk to them about their experience working with the manufacturer, including the quality of products produced and adherence to delivery schedules. This will give you a good idea of the contractor’s level of expertise and reliability.

Rigid-flex circuits are more reliable than conventional PCBs because signals don’t have to travel across connectors or solder connections, which can cause signal degradation. Furthermore, rigid-flex circuits have fewer cross-sectional changes in conductors, which can reduce signal interference and electromagnetic interference. This makes them a popular choice for complex, high-speed applications in industries like aerospace, defense, and automotive. In addition to providing the highest-quality manufacturing, a trusted rigid-flex PCB manufacturer will offer exceptional customer support and quality control. They will be able to address your questions and concerns quickly, and they will make every effort to exceed your expectations.